Product Description

YW explosion-proof liquid sewage pump product overview

YW submerged sewage pump is a vertical liquid type structure. When working, the pump body is immersed in water, the depth of liquid can reach 0.5~5m, and the unique single blade or double blade impeller structure can effectively pass the pump diameter 5 times. The fibrous material and solid particles having a diameter of 50%. The product implements the JB/T6525-92 "Technical Conditions for Centrifugal Sewage Pumps" standard.

YW explosion-proof liquid sewage pump product features

1. Variable liquid level installation depth: The unit is a vertical liquid type structure, which can be installed according to the requirements of users. It is extremely convenient to use.

2, single or double pipe installation: This type of pump according to user requirements to choose different installation methods; can choose single or double pipe installation.

3, reduce maintenance costs: the use of new materials made of mechanical seals, and high-quality bearings, greatly improving the safety of the seal and the reliability of the unit.

4, strong flow capacity: special impeller anti-blocking design, to ensure efficient operation and no blockage.

YW explosion-proof liquid sewage pump working conditions

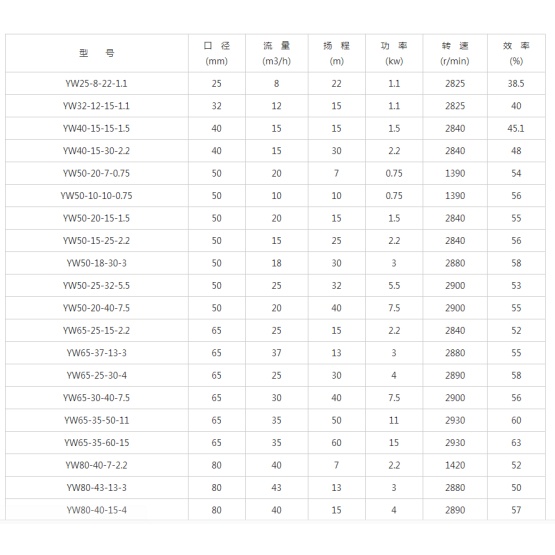

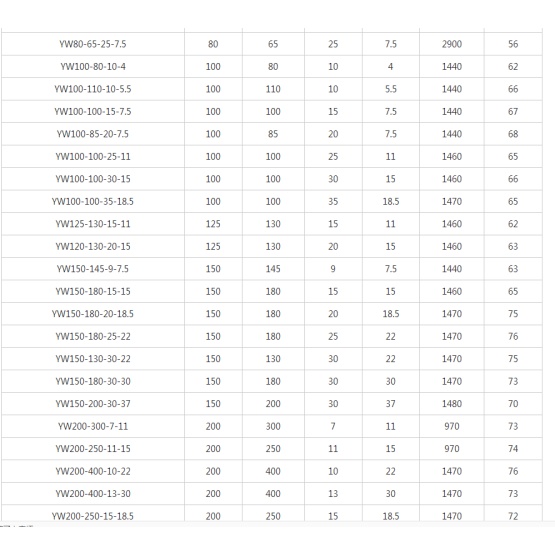

Flow rate: 2 ~ 850 m3 / h

Head range: 3 ~ 45m

Rated speed n: 1450 ~ 2900r / min

Medium temperature: -15 ° C ~ +60 ° C

Medium density: ≤1.3×103kg/m3

Media PH value: 5 ~ 9

System high working pressure: ≤0.6Mpa

Wastewater from enterprise units. Urban sewage treatment plant discharge system. Subway, basement, Sewage discharge from hospitals, hotels and high-rise buildings. Sewage drainage station in residential area. Municipal engineering, discharge of mud in construction sites. The water supply device of the waterworks. YW submerged sewage pump farm sewage discharge and rural farmland irrigation. YW submerged sewage pump exploration mine and water treatment equipment supporting. Instead of shoulders and shoulders, take the river mud. The YW submerged sewage pump uses the condition water temperature ≤ 60 ° C, and the liquid PH value is 4 to 10.

How to use and precautions

1. Before using the pump, carefully check the pump and motor for damage. Check the fastener fastening.

2. Turn the pump to check for friction. Also check the concentricity of the pump shaft and the motor shaft. The deviation of the outer circle of the two coupling shafts does not exceed 0.5mm.

3. Connect the pipeline of the pump outlet. A bracket should be provided. It is not allowed to add the weight to the pump body.

4. The pump must be equipped with a fully automatic pump control cabinet without special circumstances. Do not connect the grid directly or use the knife switch to switch on the current. Make sure the pump is running normally.

5. Do not operate the pump for a long time under low lift (usually the head should not be lower than 60% of the rated head). It can be controlled within the recommended lift range. The waterproof pump burns the motor due to overload.

maintenance

1. The pump should be managed and used by a special person. Regularly check whether the circuit and pump of the pump are working properly.

2. After each use, especially for thicker and more viscous slurry, the pump should be placed in dehydration for a few minutes to prevent deposits in the pump. Ensure the pump is clean.

3. Under normal conditions, the pump should be filled or replaced with oil (10-30# oil) after every 300-500 hours of use. Keep the mechanical seal in good lubrication and improve the service life of the mechanical seal.

4. The sealing ring between the impeller and the pump body has a sealing function. If the sealing ring is damaged, it will directly affect the performance of the pump. If necessary, it should be replaced.

.png) Contact Now

Contact Now