Product Description

IJ series corrosion resistance is a single-stage single-suction cantilever centrifugal pump. Its marking, rated performance point and installation size are in accordance with GB/T5662-1985 standard, equivalent to ISO2858.1975. The manufacturing technical conditions are in accordance with ISO5199 standard. Based on the IH series pump, the new product is optimized according to the foreign new technology and combined with the user's actual use. It is the same type of pump as the nationally promoted IH type, and its basic installation size is equivalent to the IH type.

Special pump for phosphating solution IJ HJ corrosion-resistant pump Corrosion-resistant and wear-resistant stainless steel horizontal centrifugal chemical pump

Introduction:

IJ series corrosion resistance is a single-stage single-suction cantilever centrifugal pump. Its marking, rated performance point and installation size are in accordance with GB/T5662-1985 standard, equivalent to ISO2858.1975. The manufacturing technical conditions are in accordance with ISO5199 standard. Based on the IH series pump, the new product is optimized according to the foreign new technology and combined with the user's actual use. It is the same type of pump as the nationally promoted IH type, and its basic installation size is equivalent to the IH type.

Structural features

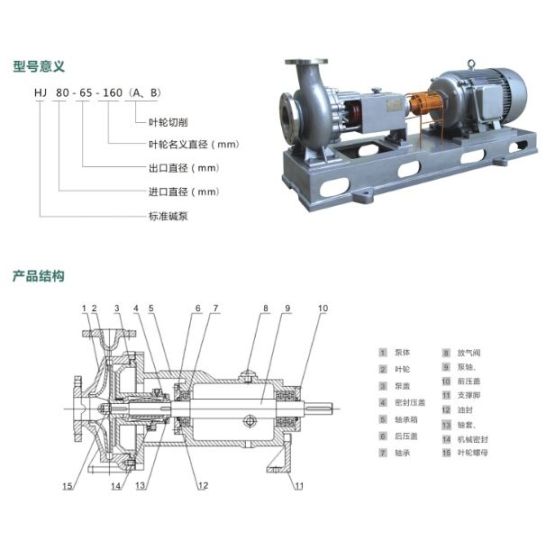

The structural characteristics of the pump are: IJ type anti-corrosion chemical alkali pump is designed with advanced hydraulic model, which has high efficiency and is energy-saving product. In the structural design, it draws on the international ANSI standard, which increases the shaft diameter, shortens the cantilever, and improves the running stability. Working temperature up to 175 ° C, can transport suspended particles less than 3mm, containing less than 5% liquid. Widely used in alkali, acid, petrochemical, environmental protection and other industries. The pump cover is fixed on the frame through the stop, and then the pump cover is clamped in the middle by the pump body connection. The pump body is axially sucked, radially discharged, and the foot is supported, and can be directly fixed on the base. And supported by the suspension bracket on the base.

Direction of rotation of the pump: The pump is directly driven by the motor through the coupling and rotates clockwise as seen from the motor end.

Pump shaft seal type:

Mechanical seal: specially designed into the inner end of the injection type single end, the moving ring is fixed, the static ring compensates the machine seal, the sealing chamber is filled with eight pressure water, the friction end face is flushed, and the cooling effect is also achieved.

The material of the pump: the over-current parts of the pump are made of stainless steel. The user can select the material of the over-current component (ie pump body, pump cover and impeller) of the pump according to the corrosion of the pump. The slurry containing less than 50% solids in the process and the medium containing the crystalline impurity medium.

IJ stainless steel alkaline pump

Application areas:

It is suitable for the ammonia brine mother liquor produced by soda ash and ammonia chloride in the alkali industry, the normal temperature caustic alkali produced by chlor-alkali, the chlorine product and the electrolyte of chlorate, hypochlorite and metallurgical electrolytic copper nickel to produce cobalt acid. The mist liquid, the mineral slurry for producing zinc, the vanadium acid for producing vanadium, the acid and urea solution for producing gold, and the electroplating for the steel industry.

Model: IJ\HJ80-65-125

Caliber range: 32-100mm

Flow range: 12.5-100m3/h

Head range: 20-125m

Compared with the IH pump, the IJ chemical pump structure has the following characteristics;

1. Shorten the cantilever of the impeller and thicken the diameter of the shaft;

2. The volute and pump casing of the asymmetric section have no ring;

3. Adopt three imported bearings;

4. It is equipped with a new type of seal similar to foreign advanced double mechanical seals or packing seals.

Due to the above structure, the pump has the following advantages:

1, can transport high viscosity or solid medium, then the pump efficiency is higher than IH pump;

2. The asymmetric cross-section volute reduces the impact loss of the fluid and shortens the size of the pump casing;

3. Increase the strength of the shaft and reduce the deflection of the rotor, so the operation is stable and the sealing life is long;

4. The impeller nut and the impeller are integrated to improve the inlet condition of the pump and improve the anti-cavitation performance of the pump;

5. The advanced shaft seal form makes the sealing effect better and reduces the leakage of the pump;

6. The gap of the pump can be adjusted without disassembling the pump casing and the impeller, which reduces maintenance time and saves maintenance costs.

use

· Alkali industry: ammonia brine mother liquor for soda ash and ammonia, co-alkali production, room temperature caustic for chlor-alkali production, chlorine products and chlorate, hypochlorite.

· Non-ferrous metallurgy: electrolyzing copper-nickel electrolyte, producing cobalt acid mist, producing zinc mineral slurry, producing vanadium ammonium vanadate, and producing gold acid thiourea liquid.

· Steel industry: electroplating, pickling, waste acid treatment.

· Acid industry: nitric acid, sulfuric acid, hydrochloric acid, phosphoric acid, acetic acid, etc.

· Petrochemical: Petroleum refining acetaldehyde, the manufacture of alkyl benzene.

· Synthetic fiber and plastics industry: polyester, PVC production, textile, printing and dyeing industry.

· Paper industry: delivery of pulp cooking liquor and bleach.

· Fertilizer industry: production of urea and ammonium nitrate.

· Pharmaceutical industry: production of medicines and pesticides.

· Environmental protection: delivery of acid mist.

· Marine engineering: seawater desalination, offshore oil production equipment, coastal power stations, vacuum salt production, etc.

.png) Contact Now

Contact Now